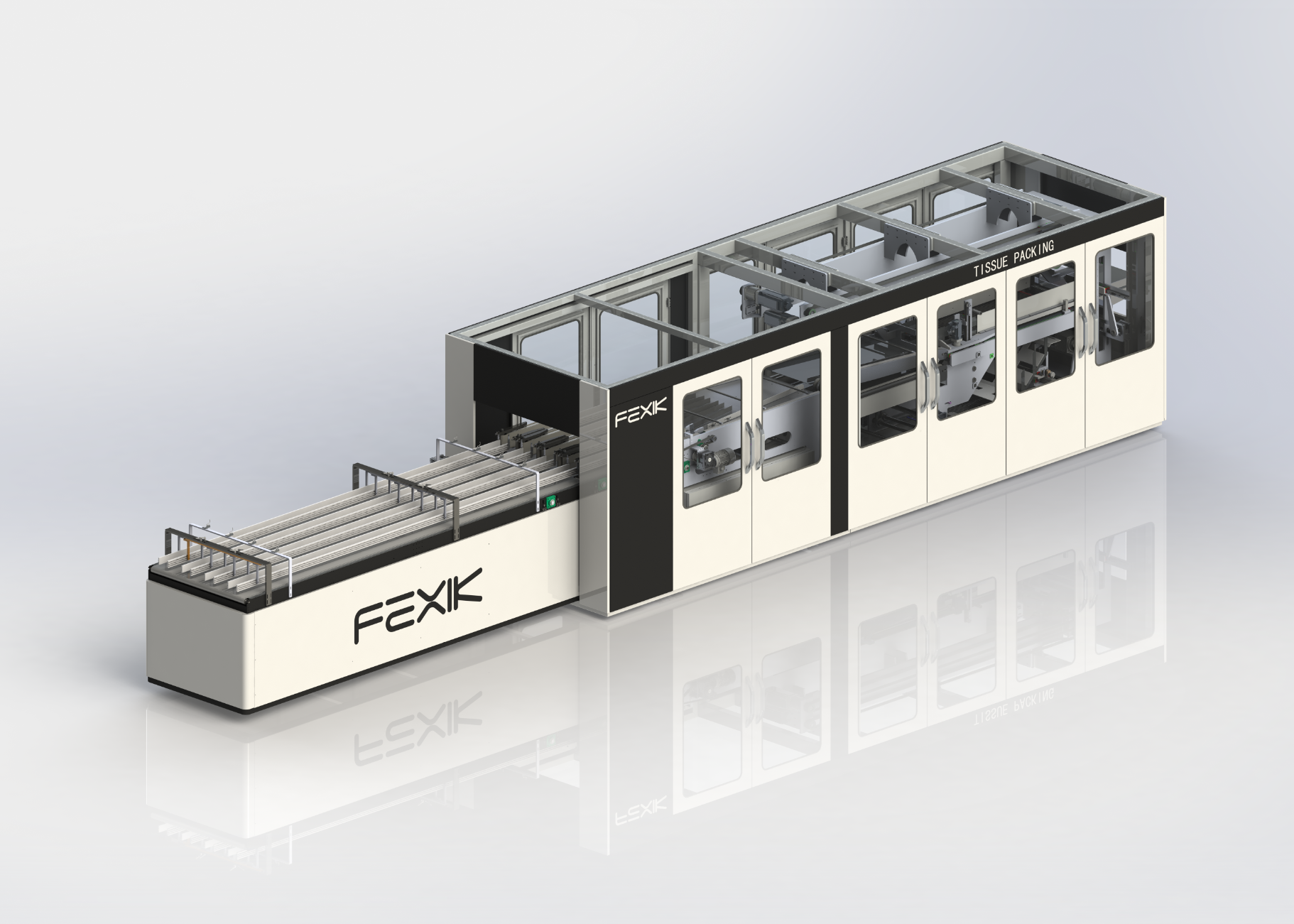

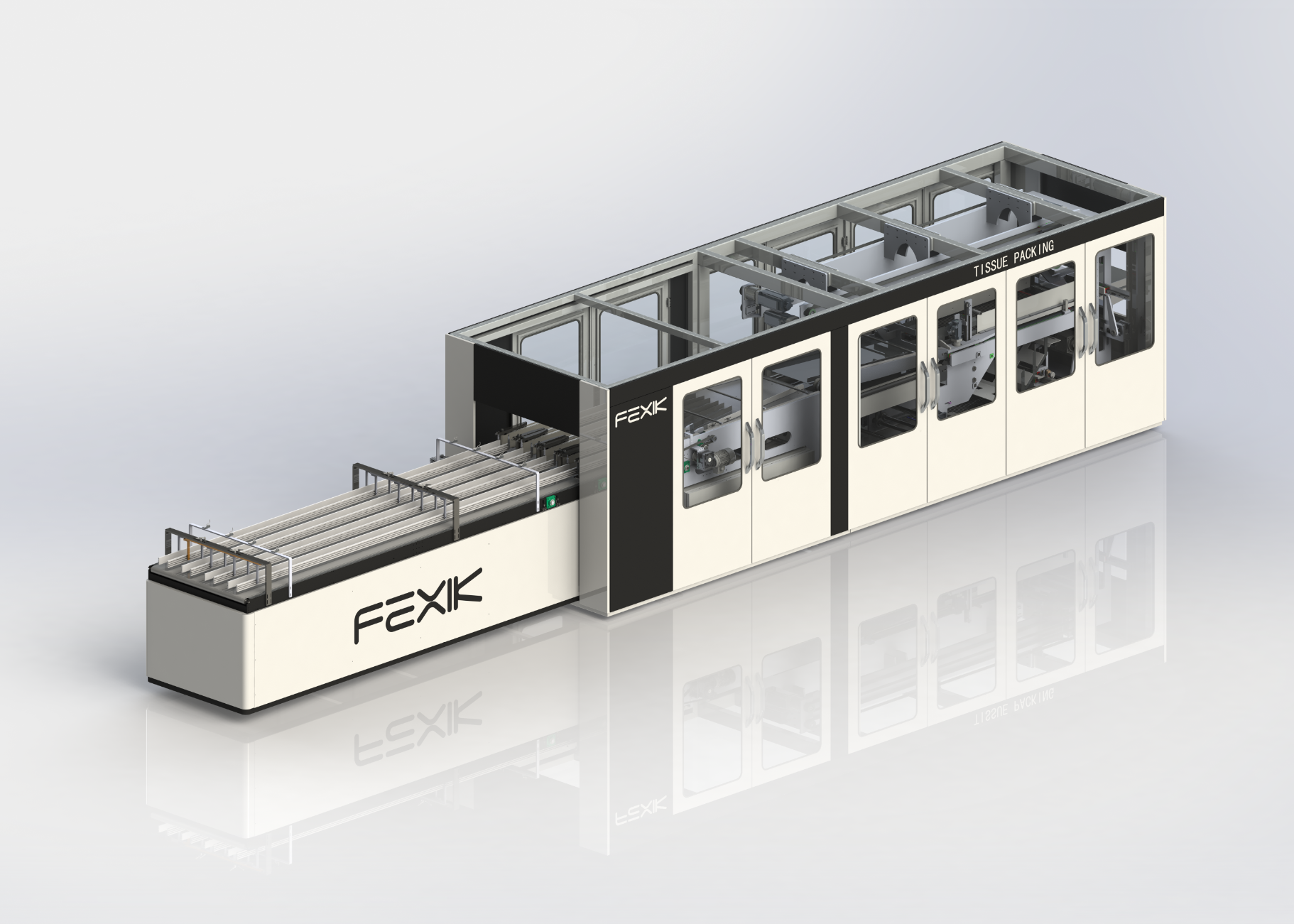

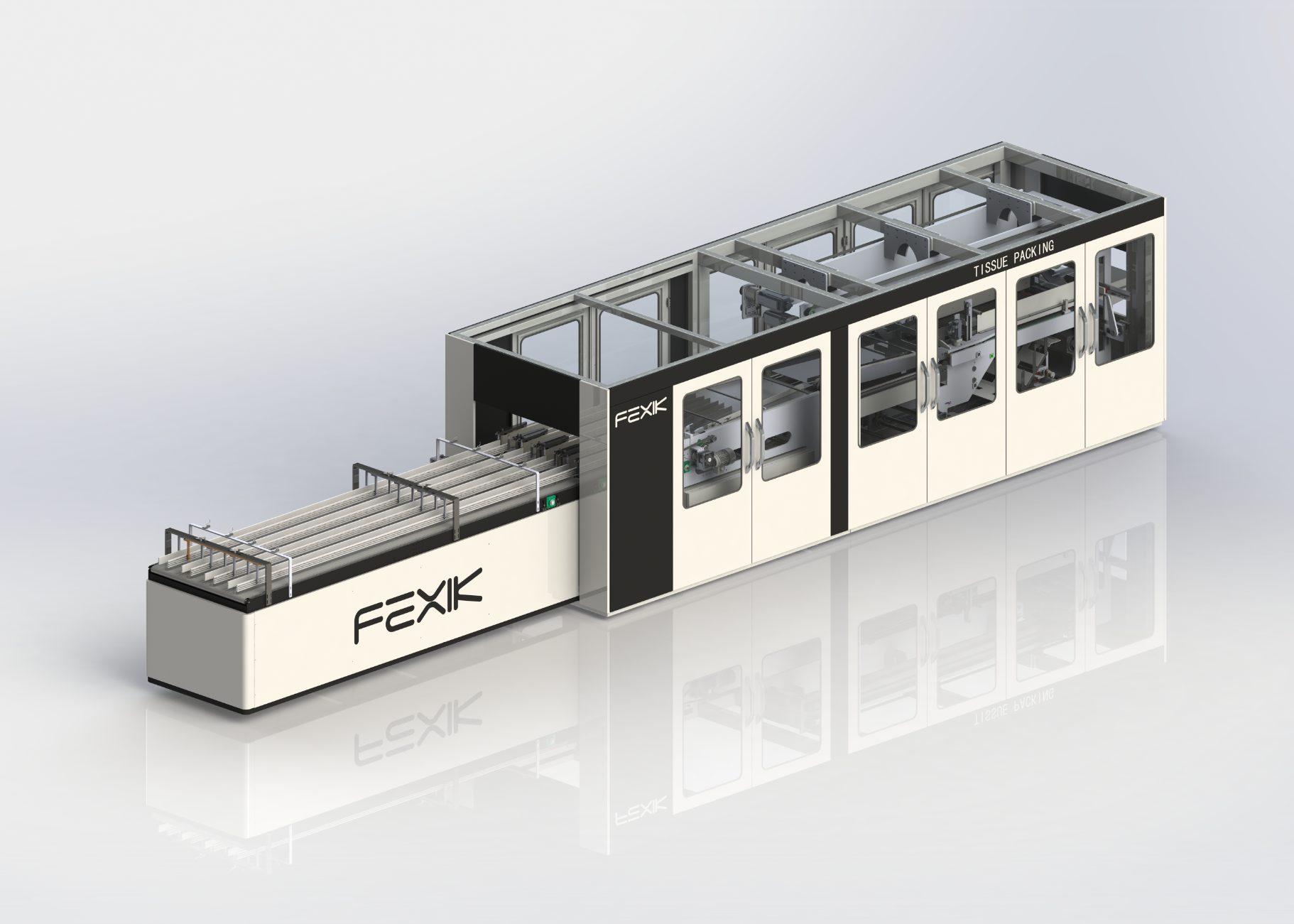

F-T3 model packing machine is to pack toilet paper rolls kitchen towel in a bundle. It has stable performance is easy to operate.

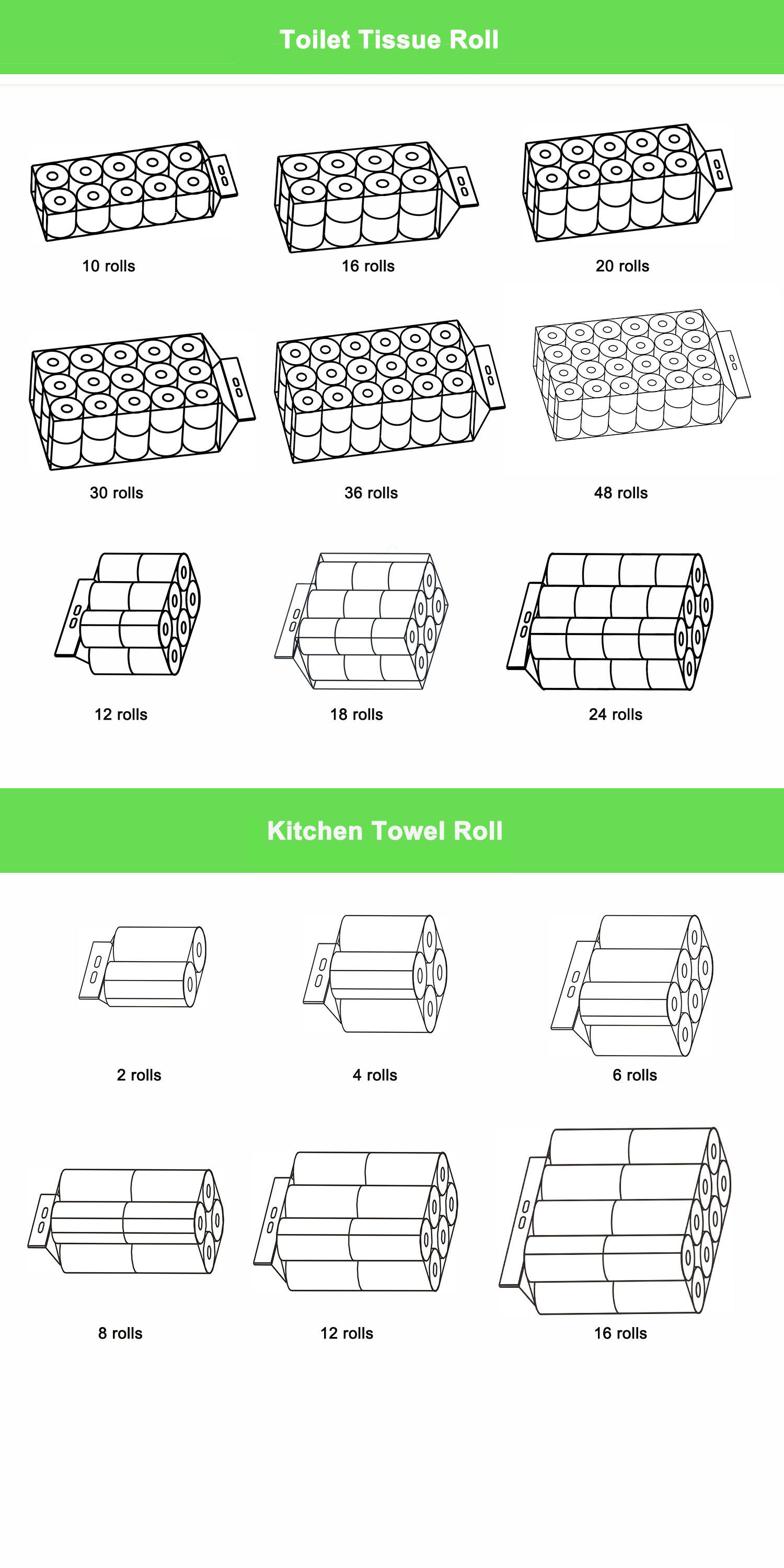

1)The double-layer packaging machine provides a variety of packaging configurations for toilet roll kitchen towel, which is suitable for automatically producing toilet paper kitchen paper in all directions with 1 layer 2 layers.

2)Using pre-made bags as packing material.

3)The innovative infeeding design: the rolls are launched in the number of lanes according to packaging configuration needed, which is set by HMI, in the single layer double layers into in-feed section. Carbon bars convey the group of rolls on the board, in the rolls are waiting for the pushing device push them into the pre-made bag.

Rolls launcher includes 4 "dousers", each servo motorized, to realize 1 to 4 lanes pack configuration. Servo motors provide counting of the exact number of rolls in order to create desired pack configuration a specific control-loop system checks the exact roll length adjusting speed/position during the machine cycle.

Layer system controlled by servos runs automatically according to the packaging configurations selected on HMI. This design realizes formats changing of different configurations 1 to 4 channels, 1 to 2 layers freely quickly. It also ensures that the distribution of paper rolls of various packaging configurations is accurate during operating in high speed there will be no paper getting stuck situation.

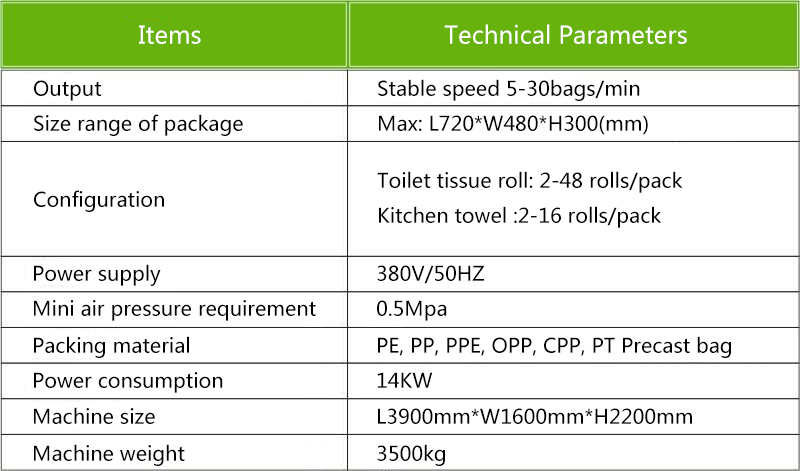

4)Adopting automatic servo control system, all motions functions are fully controlled by 19 independent servo axis.

5)Humanized HMI assists the operation of machine conversion of speed configurations. Alternative options for many packaging configurations show on HMI.

6)The innovative design of the heat-sealing system makes the heating uniform stable, to ensure the bag sealing in great quality.

7)The use of motor adjustment is convenient quick. Format changing is extremely easy fast.

8) A new better bags loading opening system is designed for the packaging machine to ensure that the operation speed can be achieved more than 25 bags/min more when packaging a large configuration. The cost of machine maintenance is very low, the machine is small, occupying less area.