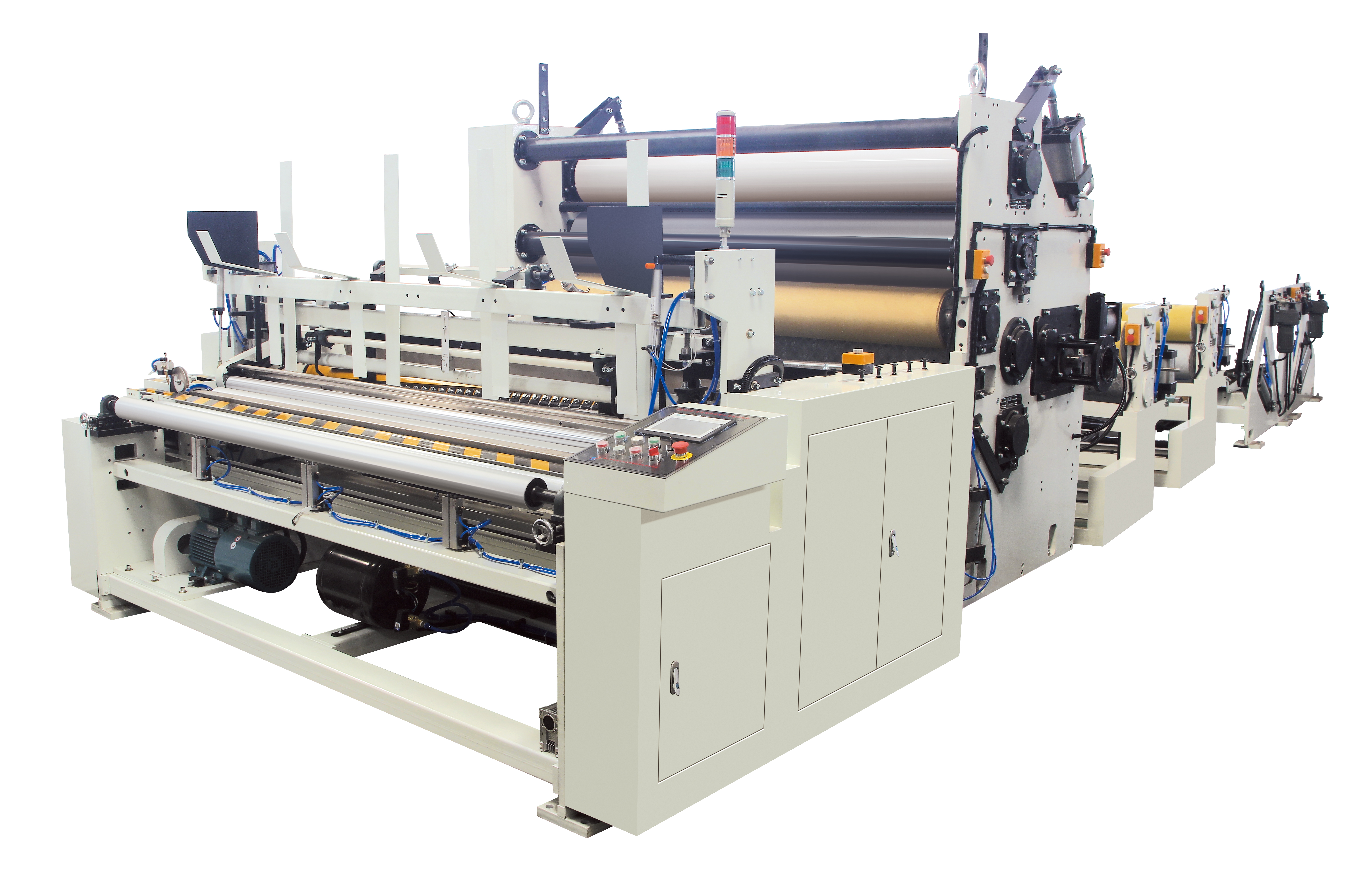

1)With man-machine interface, Chinese English switching function, synchronous frequency conversion drive.

2)Adopt PLC control system, easy to operate.

3) When the paper tube core unit cannot detect the paper tube core the paper tube core is depleted, the machine will issue an alarm to tell the operator worker to put the paper tube core on the core bracket.

4) The tightness of the winding is adjustable, it can produce paper rolls with different tightness.

5)When the previous paper log is under winding, the next paper core is ready.

6)When the finished log come to tail sealer, trimming, glue spraying sealing can be finished at the same time.

7)Full embossing unit gluing compound unit, side embossing unit, need to be ordered by the customer.

8) Independent wall-type paper backstand, the structure is simpler stronger, easy to clean.